Don’t just resolve it: Dissolve it!

Problem-solving is integral to systems development like yin and yang. Developing systems can lead to problems because of errors, discrepancies, misinterpreted or missing requirements, and interface incompatibilities. Those problems can be resolved by decomposing the problem into atomic sub-problems, finding the underlying root cause, and thus removing the defect from the overall system. A different approach to problem-solving is redesigning the system that causes or contains the problem so that the original problem no longer exists. The idea of making a problem “irrelevant” instead of gradually improving system components stems from Russell Ackoff, a system-thinking pioneer who referred to this way of problem-solving as “dissolving.” He argued that most problems are interconnected and interdependent with other issues in a larger system, rather than caused by isolated deficiencies. Therefore, according to Ackoff, the best way to deal with them is to improve the system holistically and creatively rather than optimizing system parts.

This approach differs from other problem-solving methods, such as Six Sigma, which aims to reduce variation and defects in existing processes by applying statistical and analytical data analysis. Six Sigma tries to improve the quality of system parts to make them more efficient rather than questioning and redesigning the system. Ackoff encourages a more radical rethinking of systems to eliminate problems at their source. Other fundamental approaches could also be applied, such as Design Thinking–a human-centered and iterative process of finding and solving problems by empathizing with users, visualizing the problem, ideating solutions, and empirically testing possible improvements. Design thinking harmonizes with Systems Thinking, as it emphasizes the importance of understanding the context and the needs of the stakeholders involved in the problem, as well as the feasibility and viability of the solutions.

Another related idea is Lean Thinking. It is a philosophy of eliminating waste and maximizing value in any process by focusing on customer satisfaction (akin to “customer value” or “added value”), continuous improvement, and interdisciplinary collaboration. Lean Thinking encourages experimentation and learning from failures and empowers involved stakeholders to make decisions.

Reductionism is another strategy. Unlike holistic Systems Thinking, reductionism separates complex phenomena into smaller and simpler components and analyzes them in isolation. Reductionism ignores the emergent properties and behaviors of the whole system and may lead to oversimplification or even misunderstanding of the problem.

Another approach to problem resolution is linear thinking, which assumes that problems and solutions are straightforward and follow a logical sequence of cause and effect. However, linear thinking fails to account for the feedback loops, delays, and nonlinearities typical of most nontrivial systems and may result in suboptimal solutions.

In contrast to such strategies, the Systems Thinking idea of problem-solving tends to be successful in cases where the problem complexity stands in the way of gradually (or continuously) improving a flawed system. Systems Thinking encourages problem-solving in a “disruptive,” creative way. That allows us to see the big picture, the occasionally intentionally ignored or suppressed root causes of the problems, and the potential for improving the overall system landscape. Systems Thinking strongly correlates with the culture of learning and experimentation, where problems are seen as opportunities for innovation and improvement. This approach resonates with highly motivated experts who thrive at creativity and quantum-leap-like thinking, which results in increased motivation for the entire project team.

How problem resolution based on Systems Thinking works.

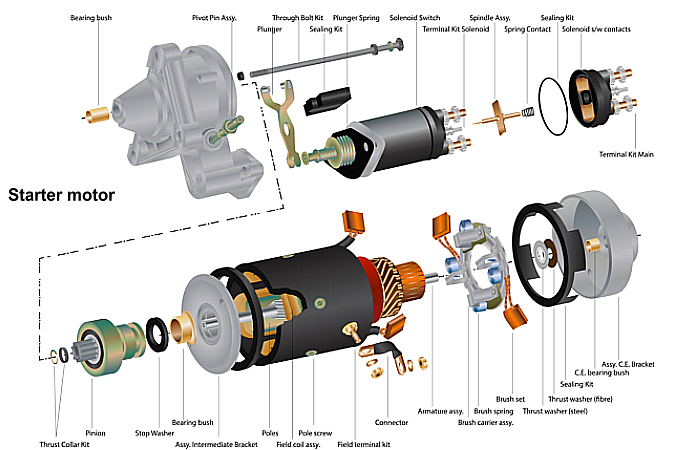

More than a century ago, to start a car, one had to attach a crank to the engine and turn it several times, hoping it would eventually start. It was a task that required a lot of physical effort, and sometimes, it could result in broken wrists or hands. Many attempts were made to improve the crank, such as better handles that would automatically release when the engine started, advanced timing controls, priming mechanisms (manually injecting fuel into the cylinders), etc. After a friend of the inventor Charles Kettering died from a backfiring engine while trying to start one of those cars, Kettering decided to “dissolve” this problem by inventing an electric starter in 1911. That ended all the other solutions that were gradually implemented before his invention.

This example shows Systems Thinking by being creative, thinking outside the box, using a different technology (electrical motor), focusing on the customer’s needs, and taking a radically different approach to the whole system (completely changing a part instead of slowly improving it).

While Systems Thinking may sound “sexy,” other problem-solving methods may have advantages and disadvantages. We have summarized some of those aspects below:

| Method | Advantage | Disadvantage |

| Systems Thinking | Allows for a holistic understanding of the system and how its components interact with each other. | Can be complex and time-consuming to analyze all the interactions and interdependencies. |

| Six Sigma | Reduces defects and variations, leading to improved quality and consistency. | Can be rigid and induce inflexibilities, possibly discouraging creativity in problem-solving. |

| Design Thinking | Focuses on meeting the needs and preferences, focusing on customer satisfaction. | Can be time-consuming and may not always result in practical or feasible solutions. |

| Lean Thinking | Improves efficiency and reduces waste, focusing on improved value for the customer. | May not always consider the long-term sustainability or impact of the solutions. |

| Reductionism | Makes complex problems or systems more manageable and easier to solve. | May not consider the interactions and interdependencies between the parts or elements, potentially leading to incomplete or suboptimal solutions. |

| Linear Thinking | Easy to understand and follow, and can be effective for simple problems or systems. | May not be effective for complex problems or systems with multiple causes and effects or non-linear relationships. |

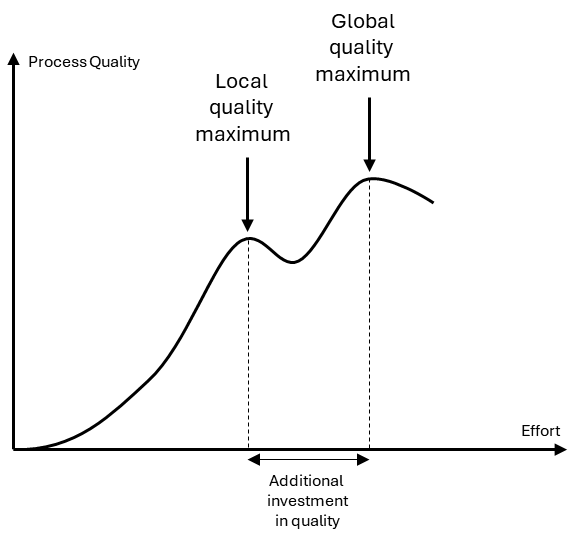

The Systems Thinking idea of problem-solving tends to be successful in cases where the problem complexity stands in the way of gradually (or: continuously) improving a flawed system. Continuous improvement fails when systems quality reaches a local maximum–a quality “plateau.”

Leaving a local maximum requires additional energy and a risk-taking attitude, so the effort to further improve a system is often shunned. In such cases, Systems Thinking offers a solution by encouraging disruptive ideas, which allows the systems to “nudge” out of the local maximum towards a better overall result.

CORE SPICE is derived from the Systems Thinking principle

Systems Thinking encourages problem-solving in a “disruptive,” creative way. That allows us to see the big picture, the root causes of the problems, and the potential for improving the overall system landscape. It strongly correlates with the culture of learning and experimentation, where problems are seen as opportunities for innovation and improvement. This approach resonates with highly motivated experts who thrive at creativity and quantum-leap-like thinking, which results in increased motivation for the entire project team.

CORE SPICE strongly encourages disruptive Systems Thinking, especially in software-intensive development, formulated as a principle of ECST (Effective Critical Systems Thinking). ECST helps teams understand and address complex problems in software engineering, such as stakeholder needs, disruptive system properties, resolving constraints, minimizing risks, and dealing with systems trade-offs.

Problem-solving by “dissolution,” as proposed by Russell Ackoff, differs from other problem-solving methods, such as Six Sigma, Design Thinking, Lean Thinking, Reductionism, and Linear Thinking. Systems Thinking is superior when the task is to solve complex and interconnected problems. As the automotive industry faces unprecedented challenges in EV and software-defined vehicle development, ECST is a way to escape this conundrum.

The paradigm shift towards Systems Thinking is not just a methodology but a mindset that emphasizes systemic change. ECST encourages achieving groundbreaking, disruptive solutions, which we urgently need to weather the storms of the current challenges faced in the automotive industry.

Let’s start a conversation on LinkedIn or X.com (formerly Twitter).